Engineering Technology Facilities

Engineering Technology Innovation Hub

Phase one of the Engineering Technology Innovation Hub was completed in the fall of 2021 with the Robotics Lab on the Middletown Campus featuring industrial robot training carts and classroom computers equipped with simulation software.

Upon completion, the Engineering Technology (ENT) Innovation Hub will feature:

- A home for the ABET-Accredited degree programs in Mechanical, Electrical and Computer, Electro-mechanical and Robotics Engineering Technology, along with the ENT certificate and credential programs in manufacturing, computer-aided design, and robotics.

- Training rooms and dedicated laboratory spaces for offering technology-focused professional development workshops, continuous education seminars.

- A center for innovation and engineering entrepreneurship that will provide opportunities for ENT students to grow as engineer-entrepreneurs and help the community to design and develop innovative patentable engineering solutions.

- A Research Studio and Innovation Lab for student and faculty-led sponsored research, development, and prototyping services for area industry and communities.

- A workplace for ENT students to gain experiential learning and internship experiences.

- Collaborative work areas and Maker spaces for conducting high school workshops, senior design project activities, and other related community outreach projects.

- Exhibit space for showcasing Engineering Technology senior design and faculty research projects and innovations.

Computer Labs

Location: Phelps Hall, Rooms 103 & 305

Installed and working software

Windows 7 64 bit

Adobe AIR

Adobe Media Player

Adobe Reader X

Adobe Flash for 32 bit IE & Firefox

Adobe Shockwave

Adobe Creative Suite CS5 (Photoshop, Dreamweaver, Illustrator, Flash, etc.

Adobe Acrobat Pro

Apple Quicktime with iTunes

Aleks

ARCGIS 10

Hawkes Learning System Prealgebra Fall 2010 Student

Google Earth

Microsoft Visual Studio 2010

Microsoft SQL Server Express 2005

11 Microsoft SQL Server 2005 Management Studio

Microsoft Office 2010

Microsoft Silverlight

Microsoft .NET Framework 1.1 ** Compatibility Problems **

Microsoft .NET framework 2.0, 3.5, 4

Microsoft FrontPage

Microsoft Project 2010

Microsoft Visio 2010

Windows Live Movie Maker

Windows Live Photo Gallery

NOTE: There are no plugins installed for 64-bit IE

Minitab

Mozilla Firefox

PASW Statistics 10 * formerly called SPSS *

Peachtree Complete Accounting 2011

Pearson TestGen 7.4

Real Player

Turning Point

Sun Java 6 update 26 jdk & jre 32 bit

VideoLAN VLC

MUNet folder

PuTTY a secure shell client

WinSCP a secure FTP client

7-Zip file compression software

LabVIEW

Autodesk Mechanical

Autodesk Inventor

Working Model

MATLAB

Solid Edge

Location: Thesken Hall, Room 106

The lab has 25 Dell Optiplex 980 workstations with 4GB of RAM running Windows 7 (x64). This lab is primarily used to teach following courses:

ENT 135: Computer Aided Drafting (AutoCad)

ENT 235: Computer Aided Design (Solid Edge)

ENT 301: Dynamics

ENT 355: Introduction to Finite Element Analysis

ENT 416: Mechanisms for Machine Design

| Software | Manufacturer | Application |

|---|---|---|

| .Net Framework 4.5 | Microsoft | Programming |

| 7-Zip 9.20 | Igor Pavlov | File Compression |

| Access 2010 SP1 | Microsoft | Database |

| Acrobat Reader 11.0.2 | Adobe | Media Player |

| Acrobat X Pro | Adobe | Graphic Design |

| After Effects CS6 | Adobe | Video Editing |

| Alice 3.1.58.0 | www.alice.org | Programming |

| Amos 21 | IBM | Data Analysis |

| ANSYS Fluent 14 | ANSYS | Engineering |

| ArcGIS 10.1 | ESRI | Mapping |

| Audacity 2.0.2 | Audacity Developer Team | Audio Editor |

| Audition CS6 | Adobe | Video Editing |

| AutoCAD 2013 | Audodesk | Engineering |

| Bridge CS6 | Adobe | Graphic Design |

| Chrome 26.0.1410.64 | Web Browser | |

| Compass ESL | ACT | Assessment |

| CPS 10 Client (Centricity) | GE | Electronic Medical Records |

| Crimson Editor v3.70 | Emerald Editor | Programming |

| Debrief Viewer 2.1.1 | Laerdal Medical | Nursing |

| DNR Garmin | Minnesota DNR | Mapping |

| Dreamweaver CS6 | Adobe | Web Development |

| DrJava 20110822-r5448 | Rice University | Programming |

| DS Agent | Altiris | Control Agent |

| Earth 7.1 | Mapping | |

| Eclipse 4.2.1 | Eclipse Foundation | Programming |

| Eclipse with Android SDK | Eclipse Foundation | Programming |

| Excel 2010 SP1 | Microsoft | Spreadsheet |

| Firefox 20.0.1 | Mozilla | Web Browser |

| Fireworks CS6 | Adobe | Graphic Design |

| Flash Player 11.7.700.169 | Adobe | Media Player |

| Flash Professional CS6 | Adobe | Video Editing |

| Graphical Analysis 3.4 | Vernier | Physics |

| iCloud Control Panel 2.1.1 | Apple | File Storage |

| IDRISI Taigi 16.05 | Clark Labs | Mapping |

| Illustrator CS6 | Adobe | Graphic Design |

| Imagine 2011 | ERDAS | Mapping |

| InDesign CS6 | Adobe | Graphic Design |

| Internet Explorer 9 | Microsoft | Web Browser |

| iTunes 11.0.1.12 | Apple | Media Player |

| Java SE (JDK) 7u21 | Oracle | Programming |

| Kurzweil 3000 11.0 | Kurzweil Educational Systems | Accessibility |

| LabVIEW 2012 | National Instruments | Engineering |

| Lame Encoder for Audacity 3.99.3 | Audacity Developer Team | Audio Editor |

| Logger Pro 3.4.6 | Vernier | Physics |

| MathType v6.7 | Design Science | Equation Editor |

| MATLAB 2013a | MathWorks | Data Analysis |

| Media Encoder CS6 | Adobe | Video Editing |

| Medical Office Practice | Delmar Applications | Transcription |

| Minitab 16 | Minitab Inc. | Data Analysis |

| Movie Maker 2.6 | Microsoft | Video Editor |

| Muvizu | Digimania | Animator |

| mySQL 5.6.13 | Oracle | Programming |

| mySQL Workbench 5.2 CE | Oracle | Programming |

| NetSmk | Networking | NetSimK |

| NetSupport School 11 | NetSupport, Inc. | Classroom Monitoring |

| Notepad++ 6.2.2 | Don Ho | Text Editor |

| Payroll Accounting 2013 | Klooster & Allen | Accounting |

| PCSpim 9.1.4 (MIPS) | James Larus | Programming |

| Photo Story 3 | Microsoft | Photo Editing |

| PhotoShop CS6 | Adobe | Graphic Design |

| Power Point 2010 SP1 | Microsoft | Presentation |

| Prelude CS6 | Adobe | Video Editing |

| Premiere Pro CS6 | Adobe | Video Editing |

| Project 2010 | Microsoft | Planning |

| Publisher 2010 SP1 | Microsoft | Publishing |

| PuTTY 0.62 | Simon Tatham | Programming |

| QSEN | American Association of Colleges of Nursing | Nursing |

| Quicktime 7.7.3 | Apple | Media Player |

| RAPTOR 4.0.6.0001 | Martin Clarlisle | Programming |

| Real Player Alternative 2.0.2 | Gabest | Media Player |

| Refine 2.5 [r2407] | Data Analysis | |

| RM Easiteach 3.6 | Lightbox Education | White Board |

| RoboMind 3.0 | Arvid Halma | Programming |

| Sage 50 | Sage | Accounting |

| Scratch 2.0 | Programming | MIT Media Lab |

| Shockwave Player 12.0.2r122 | Adobe | Media Player |

| Silverlight 5.1.10411.0 | Microsoft | Media Player |

| Smart Notebook | Smart | White Board |

| Solid Edge ST5 | Siemens PLM Software | Engineering |

| SpeedGrade CS6 | Adobe | Video Editing |

| SPSS 21 | IBM | Data Analysis |

| SPSS Modeler | IBM | Data Analysis |

| SQL Server 2008 | Microsoft | Programming |

| Strawberry Perl | Programming | Perl.org |

| Tableau Desktop 8.0 | Tableau | Data Analysis |

| Tax Act 2012 | 2nd Story Software | Accounting |

| TestGen Plug-in 7.4 | Pearson Education | Media Player |

| TINA | Design Soft | Engineering |

| Turning Point 5.0.0 | Turning Technologies | Clickers |

| TurningKey 1.4.1 | Turning Technologies | Clickers |

| TurningPoint Anywhere 3.2.1 | Turning Technologies | Clickers |

| Type Faster | Ktouch Tying Tutor | Keyboarding |

| Visio 2010 SP1 | Microsoft | Graphic Design |

| Visual Studio 2010 SP1 | Microsoft | Programming |

| VLC 2.0.8 | VideoLAN Team | Media Player |

| VMWare Workstation 9.0.1 | VMWare | Programming |

| Word 2010 SP1 | Microsoft | Word Processing |

| Working Model 2D 9.0.3 | Knowledge Revolution | Engineering |

| Zotero 3.0.11.1 | Center for History and New Media | Citations |

Research Labs

The Department of Engineering Technology at Miami University has three research labs. Students can be involved in research in different ways, such as by working towards their senior design projects.

Director: Dr. Mert Bal

This lab utilizes various levels of micro-processing and computing electronics equipment for supporting the ongoing applied research of the EMET faculty and students on the following focus areas:

Industrial Applications of Wireless Sensor Networks for Distributed Control and Monitoring.

- Structural Modeling and Energy Aware Design of Distributed Industrial Wireless Sensor and Actuator Networks.

- Mobile and Cloud Computing Applications for distributed control in Industrial Automation

- Pervasive Smart Spaces and Applications of Wearable Technologies for improving the Quality of Life.

- Prediction of Risk of fall and Balance Studies.

Major equipment used in this lab include:

- Multiple microprocessor devices

Arduino UNO and MEGA boards

Raspberry PI Platforms

TI-Tiva ARM Microprocessors

- Wireless Networking and Communication Kits

Arduino WiFi and ZigBee wireless communication Kits

TelosB Wireless Sensor Networking Boards

SunSPOT Small Object Technology for Wireless Networking

Radio Frequency IDentification Kits

Multiple Bluetooth Kits

- Industrial Programmable Logic Controllers

CUBLOC Industrial Kits

Allen Bradley SLC500 Kits

- Various sensors and wearable movement tracking devices

FitBit Sensor

TinyDuino Motion Logger

Current Sensors

Accelerometers

Acoustic Sensors

Director:

Welcome and thank you for your interest in the Design and INnovation Center (DINC) at the Department of Engineering Technology, Miami University Regionals, Ohio.

I am posting here some guidelines and comments that should help you learn more about the lab and the opportunities that may be available to you.

Join our team: Hiring student researchers

Major Activities of this lab are:

- Support undergraduate student research

- Cooperate with the faculty including ENT and other departments at Miami University (e.g., Department of MME at Miami University), and other universities for research studies

- Cooperate with the industry for research projects (automotive, aerospace, other engineering).

- Design and include lab components for ENT-310 Fluid Mechanics and other major courses

- Design and include projects for Senior Design student groups as part of ENT 497-498 courses

- Develop new courses in Fluid Mechanics, Aerodynamics and CFD areas

Why Design and INnovation Center (DINC)?

The strengths of the undergraduate programs at the Department of Engineering Technology and in DINC include having access to laboratory facilities and research opportunities in a vibrant small-school setting where faculty and colleagues take great pride in offering personalized mentoring and advising to our undergraduate students. DINC students are challenged and immersed in a collaborative, supportive, and nurturing environment made up of faculty, undergraduate students, lab assistants and technicians.

Research Assistantships (part-time or full-time), Financial Support, and Course Work as part of Research (CWR) or Research Work as part of Course (RWC) Opportunities

I am always interested in adding highly qualified, motivated, and hard-working students to the lab. To be considered for financial assistance of any form the following steps need to be taken first:

[1] Include a Personal Statement that describe why you want to study/work with Prof.Murat David J. Dinc,

[2] Be admitted for undergraduate studies and be a Miami University student,

[3] Send me email (at dincm@miamioh.edu) with the following information: the degree program you have been admitted to, the semester you started, area of research interests, your cv/resume in pdf format.

If you are a current Bachelor's of Science degree pursuing Miami University student, then send me a document including your cv/resume, transcript(s), and interests of study areas. Upon receipt of this email I will evaluate your application for a possible research assistantship or internship.

Current and Future Research Topics (in Aerodynamics, and Thermal-Fluids areas)

- Single drop, spray flow and spray cooling studies in thermal management area (current),

- Aerodynamic analysis of ground vehicles (cars, trucks, buses, etc.) aiming for drag/lift coefficient and fuel consumption improvement studies (current),

- Aerodynamic analysis of airplanes aiming for drag/lift coefficient studies (future),

- Analysis of flow around structures (buildings, etc.) for wind trajectory studies under hazardous environmental conditions (e.g., High-wind speed, tornado) (future)

Resources

Computational Resources

- Two business workstations in Thesken Hall to perform computational part of research activities. Will add more business workstations to increase computational capacity by creating a small-lab scale high-performance-computing (HPC) center.

- Variety of computational tools to utilize in research and teaching activities.

Experimental Equipment at Thesken Hall

- Subsonic wind tunnel

- Pressure transducers, accelerometers, velocity probes and other measurement tools

- 3D printers

- High-speed cameras

- Plan developing and constructing single drop and spray cooling experimental setups at Thesken Hall as part of future experimental research activities and supplemental teaching materials.

Subsonic wind tunnel with high-speed cameras

3D printers

3D printed sedan car model (one of the DrivAer model) configuration. DrivAer car model CAD files.

Thermal-Fluid Dynamics Research:

There are four major parts in my thermal-fluid dynamics related research.

- Computational Fluid Dynamics Study of the Effect of Several Parameters on the Impact of a Drop onto Dry and Wet Surfaces under Isothermal Conditions

- Computational Fluid Dynamics Study of the Effect of Several Parameters on the Impact of a Drop onto Dry and Wet Surfaces under Thermal Conditions

- Computational Fluid Dynamics Study of the Effect of Several Parameters on the Impact of Sprays under Isothermal Conditions

- Computational Fluid Dynamics Study of the Effect of Several Parameters on the Impact of Sprays under Thermal Conditions (Spray Cooling)

Scope of Research: Single drops and sprays have many applications in biomedical, chemical and mechanical engineering (ink-jet, etc.). Sprays include millions of drop impingements per second on a surface. The impact of liquid drops and sprays onto both dry and wet surfaces has been studied by many researchers for more than a century but the complete understanding of this phenomenon is still lacking especially in thermal applications. This research includes part of single drop impact analysis and how some of the fluid and environmental parameters (e.g. gravity) may affect the single drop impact phenomenon.

Timeline: Fall 2020 and following semesters (once part 1) is completed, continue with parts 2), 3), and 4)).

Method: Computational Fluid Dynamics (CFD) approaches will be utilized. Commercially available ANSYS Fluent is the main resource of this research. ANSYS Fluent is utilized with two workstations (located in Dr. Dinc’s office) via remote access. Students can also access these workstations via remote access if needed.

Student Researchers: Planning to hire one or two students for 10 hours/week for Winter 2020 and Spring 2021 and later semesters depending on available funding.

Outcome of Research: Outcomes of this research is planned to be published and presented in journal-conference papers, symposiums (such as AIAA-DCASS), and Miami University Undergraduate Research Forum and other events and organizations at Miami University.

Sample of Single Drop Research:

Perform CFD Analysis of Single Drops and Investigate:

- Effects of liquid properties on single drop impact,

- Effects of gravity on single drop impact,

- Effects of surface contact angle on single drop impact,

- and more…

For more information about images and about sample research and other details, please contact Murat David J. Dinc.

Dimensionless Parameters

Dimensionless numbers in engineering and physics are used for data reduction of similar problem. See important parameters used in drops and spays are:

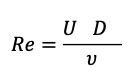

Reynolds Number:

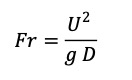

Froude Number:

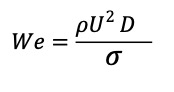

Weber Number:

| Case | Gravity (m/s 2) | We | Re | Fr |

|---|---|---|---|---|

| 1. Solar | 275 | 27.3 | 2123 | 1.8 |

| 2. Jupiter | 24.8 | 27.3 | 2123 | 20.2 |

| 3. Earth | 9.81 | 27.3 | 2123 | 51 |

| 4. Lunar | 1.68 | 27.3 | 2123 | 297.6 |

| 5. Asteroid 1999 R-36 |

0.038 | 27.3 | 2123 | 13, 157 |

Why Asteroid 199R-36 Gravity?

- Bennu (Asteroid 1999R-36) is Near-Earth Asteroid.

- Bennu (Asteroid 1999R-36) is the target of the OSIRIS-REx mission which is intended to return samples to Earth in 2023 for further study. [1][2][3]

- Corum, Johnthan (8 September 2016). "NASA Launches the Osiris-Rex Spacecraft to Asteroid Bennu," The New York Times. Retrieved 9 September 2016.

- Chang, Kenneth (8 September 2016). "The Osiris-Rex Spacecraft Begins Chasing an Asteroid." The New York Times. Retrieved 9 September 2016.

- Brown, Dwayne; Neal-Jones, Nancy (31 March 2015). "RELEASE 15-056 –NASA's OSIRIS-REx Mission Passes Critical Milestone." NASA. Retrieve 4 April 2016.

Effects of Gravity (FR number)

- Increasing gravity (decreasing the Fr number), increases maximum spread diameter. Time scales do not change.

- Effects of gravity are not very significant for lower gravity range (between Asteroid (~0) – Earth (g))

Effects of Gravity (Fr number) line graph

Maximum Spread ratio or maximum dimensionless spread diameter is obtained using this equation: Dmax / Do (maximum spread diameter / initial drop diameter)

The major outcome of the results: It is obtained from simulations that the effects of gravity (the Fr number) is very significant on maximum drop spread diameter especially at higher gravity values (lower Fr number cases). At lower gravity values (higher Fr number cases), the difference on the maximum spread diameter is not significant.

Free Tutoring Services

Murat David J. Dinc may offer students free tutoring via video conferencing (upon request and depending on the availability). Tutoring topics would include mathematics, geometry, analytical geometry, and physics-based courses. These courses are foundation of most of engineering technology courses and it is required to use them in most of the courses work.

Teaching Labs

Electrical and Computer Engineering Technology Labs

Locations: Middletown Campus: Thesken Hall, Room 102

This lab gives an opportunity to student to get acquainted into modern signal processing systems and algorithms simulation, and their implementation on hardware platform. Students can demonstrate system/algorithm performance by simulating on Matlab, reconfiguring it in embedded real-time C programs using TI Code Composer Studio (CCS), and their implementation TI fixed point DSP C55xx platform. An associated course is ENT303, which provides vibrant background in waveform analysis and digital filtering, frequency domain techniques, and introduce commonly used digital speech and image processing techniques in communication systems.

Director: Dr. Roger Seifried

Locations:

Middletown Campus: Thesken Hall, Room 102

Hamilton Campus: Phelps Hall, Room 303

This lab represents an important milestone in the journey of Electrical and Computer Engineering Technology by providing essential basics which students follow in their daily routine. This lab carries all basic components needed to understand underlying founding laws of electronics theories. This lab is equipped with passive and active components including TINA circuit simulator, function generators, oscilloscopes, AC/DC power supplies, multi-meters, and a variety of supporting electronic/electrical equipment that helps build solid practical foundation towards various degree programs.

This lab primarily serves the practical requirements of ENT192, ENT193, and ENT196 courses.

Director: Dr. Roger Seifried

Locations: Hamilton Campus: Phelps Hall, Room 305

The Internet is a vibrant constituent of everyone’s daily routine. This lab introduces essential components of the Internet and provides an IT background to students' knowledge portfolios. Students are exposed to various information technology building blocks such as software and hardware configuration of router, switch, hub and other network elements.

Director: Dr. Roger Seifried

Locations: Hamilton Campus: Phelps Hall, Room 303

The Microcontrollers and Embedded systems lab provides opportunities to learn about the basics of microcontrollers, configuration of Robotics and Automation hardware/software, and associated embedded systems standards. In this lab, students can access hardware and software associated with Arduino Controllers, Motorola 68HC12 processor, Altera FPGA evaluation platform, and TI DSP Processors.

Electromechanical Engineering Technology Labs

Director: Dr. Mert Bal

Locations: Hamilton Campus: Phelps Hall, PHE 100 & PHE 300

The Control Systems Lab in the Department of Engineering Technology contains a variety of laboratory equipment used in design and experimentation of digital and analog electromechanical feedback control systems. The equipment in this lab is mainly used in lab projects of Process Control and Interface Design (ENT 311) and Electromechanical Control Systems (ENT 418) courses.

he topics studied in this lab include principles of digital and analog data acquisition, electro-mechanical interfacing, control systems with embedded microcontrollers and programmable logic controllers, digital communication and networking, feedback control systems, state variable models, higher order system response, transient response, and stability analysis.

Major lab equipment

- Process Control Training Equipment

- Magnetic Levitation PID Control System

- Inverted Pendulum Apparatus

- Fluid Trainer System

- Motors And Controllers

- Ladder Logic Trainer

- Programmable Logic Controllers (Allen Bradley SLC500)

Lab kits

Some of the equipment used in this lab consists of ‘lab kits’. Each kit belongs to a laboratory project and contains a set of equipment and parts that are used by the students to design, build and test lab project hardware in order to perform experimentation. Typically these laboratory projects are carried out by groups of 2-4 students. Each student group is provided a lab kit to do the laboratory project of the course.

Major lab kits: ENT 311

These lab project kits are used in the Process Control Interface Design Course (ENT 311).

Digital Control Lab Project Kit- Arduino UNO Board

- LEDs and Switches

- 10K Resistor

- 10K Potentiometer

- Thermistor

- 2 ft-long plastic water tube with digital sensors

- Water container for excess water

- Ruler/engineer’s scale to measure tube diameter, heights, etc.

- Stop watch or equivalent

- Stepper Motor XY Printer/Plotter Table (See the figure below)

- Microcontroller Board with Relays

- 5V Power Adapter

Major lab kits: ENT 418

These lab project kits are used in Electromechanical Control Systems (ENT 418).

Servo Speed Control Lab Kit

Students determine the transfer function of the unit and from this design an interface to control the speed of the motor. Each Lab Kit Includes:

- DC Motor

- Motor Stand

- Speed controller

- Tachometer

- Reflective tape

Students design a CAM and use an RC servo to balance the wheel. Each Lab Kit Includes:

- Caster stand

- Servo Motor

- Servo controller

- Cam paper

- Caster wheel

Common Equipment

Common equipment in this lab is used for building and testing of various interfacing and control systems lab projects.

- Microcontroller Boards (CUBLOC & Arduino)

- LEDs and Switches

- DC Power supply units

- Digital Multimeters with RS-232 Interface

- Resistors, capacitors, inductors, diodes, transistors, and various TTL chips

- DMMs, oscilloscopes, frequency generators and scope-meters

- Breadboards and wiring

Software Used in Control Lab Projects

Each laboratory project has a software and programming component. The following software applications are used in order to complement the experiments performed in this lab.

- Microsoft Visual Studio

- Microsoft Excel

- Matlab Simulink

- CUBLOC Studio

- Arduino IDE

Director: Dr. Mert Bal

Locations: Hamilton Campus: Phelps Hall, PHE 100 & PHE 300

The Instrumentations Lab offers a variety of laboratory equipment that is utilized in design and development of electromechanical instrumentations systems for measurement and analysis of solid mechanical quantities, speed, position, and torque measurements, and pressure, temperature and flow measurements. The lab is mainly utilized by the Computerized Instrumentation (ENT401) course.

The equipment in the instrumentation lab is also used for building and testing various electrical-signal conditioning systems, data acquisition and other electronics interfacing systems such as amplifiers, multiplexers and filters.

Each kit belongs to a laboratory project and contains a set of equipment and parts that are used by the students to design, build and test lab project hardware in order to perform experimentation. Typically these laboratory projects are carried out by groups of 2-4 students. Each student group is provided a lab kit to do the laboratory project of the course.

Major Lab kits

Encoder-Tachometer Lab Project Kit

- 4-speed crank axle gearbox

- Encoder Stand

- Scotch sticky back pads

Accelerometer Lab Project Kit

- DE-ACCM3D accelerometer chip and breadboard

- 9 Volt battery with battery connector

Straub Gauge Lab Project Kit

- Strain Gauge Unit with Cantilever Beam Setup

- 330 ohm resistors

- 1KOhm Potentiometer

Affinity Law of Pumps Lab Project Kit

- Water Pump

- Bourdon Gauge

- Rotameter Flowmeter

- Bucket and Clear plastic tubes and pipe fittings

Common Equipment

The common equipment in this lab is used for building and testing of various interfacing and instrumentation lab projects listed above.

- Microcontroller Boards (CUBLOC & Arduino)

- DC Power supply units

- Digital Multimeters with RS-232 Interface

- Breadboards, switches and other small electronics components

Software used in Instrumentation Lab Projects

Each laboratory project has a software and programming component. The following software applications are used in order to complement the experiments performed in this lab.

- Microsoft Visual Studio

- Microsoft Excel

- Matlab Simulink

- CUBLOC Studio

- Arduino IDE

Director: Dr. Mert Bal

Locations: Hamilton Campus: Phelps Hall, Rooms 100 & 102

The Industrial Automation and Robotics Lab supplies a variety of common automation equipment, used in characterization, applied design, operation and troubleshooting of modern robotics and industrial automation systems commonly used in the process and manufacturing industry. The equipment in this lab is used to analyze common electrical and mechanical instrumentation including hydraulic and pneumatic equipment, automated material handling systems, industrial robot control and programming, programmable logic controllers (PLC), building automation control systems with microcontrollers and incorporating industrial SQL databases and networks.

The lab is utilized mainly for Industrial Automation Lab (ENT 402) and Modern Manufacturing Systems (ENT 407) courses.

Major Lab Equipment

- Bottling Process Simulator

- IBM SCARA Robot

- Adept SCARA robot with Vision System

- 5-Axis Mitsubishi RM-501 Movemaster Remote Controllable Robot Arm

- LynxMotion’s SSE-32 6-Axis Robot Arm

- Multiple Conveyor Systems

- A PLC-Controlled Indexing Table

- Pneumatic can crusher lab project kits

Each kit contains:

- 6-Axis Electric Robot Arm

- Soda can crusher unit with switches and a pneumatic cylinder

Common Equipment

The common equipment in this lab is used in addition to the equipment listed above for building and testing various automation systems lab projects.

- Microcontroller Boards (CUBLOC & Arduino)

- LEDs and Switches

- DC Power supply units

- Digital Multimeters with RS-232 Interface

- Resistors, capacitors, inductors, diodes, transistors, and various TTL chips

- DMMs, oscilloscopes, frequency generators and scope-meters

- Breadboards and wiring

Software used in Industrial Automation and Robotics Lab Projects

Each laboratory project has a software and programming component. The following software applications are used in order to complement the experiments performed in this lab.

- Microsoft Visual Studio

- Microsoft Excel

- IBM AML Robot Programming Software

- Microsoft SQL

- VCIMLAB Virtual Reality Robotics Training Software

- CUBLOC Studio

- Arduino IDE

Mechanical Engineering Technology Labs

Director: Prof. Rob Speckert

Locations:

Middletown Campus: Thesken Hall, Room 08

Hamilton Campus: Phelps Hall, Room 102

The Manufacturing Laboratories in Engineering Technology provide opportunities for students to demonstrate and apply the concepts of machining (turning, milling, drilling, etc.), computer numerical control (CNC) programming, CAD/CAM, 3D printing, robotics, automation/system integration, and quality control/SPC. Students utilize the lab equipment to manufacture parts and systems for their manufacturing classes, projects for other classes, and senior design projects. Students gain hands-on experience with manual machining, CNC programming, robotics programming, PLC programming and system integration. The main equipment in these labs are:

- Lathes, mills, drills, cut-off saws, and bench grinders

- CNC machines

- 3D printers

- Robots

- PLCs

- Conveyors

- Various measurement devices

- Material testing equipment

- Complete set of hand tools

Director: Prof. Gary Drigel

Location: Thesken Hall, Room 11

In the Department of Engineering Technology the Measurements and Instrumentation labs provide students with opportunities to observe, touch and interact with a wide variety measuring devices used in the design and manufacturing world. In designing structures, machinery, mechanisms, transportation systems and mechanical devices, students learn to follow traditional design processes and codes. One of the most important things to do once a design is completed is to measure its performance and compare that performance against predicted and calculated design parameters. In this way designers can insure that their design processes are valid and the predicted performance will be met. This also allows for modification of design parameters to insure accuracy in future designs.

This laboratory serves the Strength of Materials (ENT 272), Machine Designs (ENT 278), and Fluid Mechanics (ENT 310) Experimentation Techniques for Engineering Technology (ENT 404) and Senior Design (ENT 497/498) courses. The main equipment in this lab are:

- Thermocouples, Thermistors, Infrared Thermal imaging (IR) systems

- Potentiometers and Linear Variable Differential Transformer (LVDT) devices

- Load cells and Strain Gauges

- Torque Meters and Torque Wrenches

- Pressure Gauges, Manometers and Pressure Transducers

- Flow Meters and Velocity Devices

- Accelerometers

- Spring Constants

- Nondestructive Testing (NDT) Processes

- Stress Intensity Parameters

- Poisson Ratios

- Numerous Calibration Devices (gauge blocks, dead weight gauge calibration, etc.)

Director:

Location: Thesken Hall, Room 10

At the Department of Engineering Technology, Thermal-Fluids Laboratory creates opportunities for its students to demonstrate and apply the concepts of fluid mechanics, applied thermodynamics and heat transfer. Students conduct experimental studies of energy processes and learn data reduction and analysis procedures. This laboratory serves Fluid Mechanics course (ENT 310), Applied Thermodynamics (ENT 312), and Heat Transfer (ENT 415). The main equipment in this lab are:

- Centrifugal fan

- Double-size piping system for minor loss experiment

- Open loop 60-hp wind tunnel

- Viscometer

- Falling-ball viscometer

- Rankin Cycler for simulating steam power plants

- Particle Image Velocimetry (PIV)

- Thermal infrared imaging (IR) system

- Hotwire anemometer

- Air conditioning training unit<

- One-dimensional steady heat conduction equipment

- Heat conduction in fins

- Forced convection equipment

- Radiation heat transfer equipment

- CO2 gas analyzers

Director: Dr. Vipul Ranatunga

Location: Thesken Hall, Room 11

The Mechanical Vibration Lab on the Middletown campus provides hands-on experience with instrumentation used for vibration monitoring and modal analysis. The lab is equipped with a mass-spring-damper system to study the effect of structural stiffness and damping on mechanical vibrations. This system has a sophisticated excitation scheme to simulate various types of vibrations such as periodic sinusoidal vibrations, random vibrations, as well as impact and user-defined vibration signals. During the laboratory exercises, students utilize this setup to understand the free and forced vibrations and the effect of damping on vibration suppression under resonant conditions.

Another exciting laboratory instrument in the mechanical vibration lab is the electro-magnetic vibration shaker and the control system. This system provides hands-on experience with modal analysis. Test objects can be mounted on top of the vibration shaker to study the resonant frequencies and modal shapes.

Mechanical vibration lab is equipped with numerous accelerometers, displacement sensors, velocity transducers, hand-held vibrometers, etc. to provide a comprehensive coverage of instrumentation used in vibration monitoring, control, and isolation. Students taking Topics in Mechanical Vibrations (ENT 416) use this laboratory to acquire the practical experience with instrumentation related to mechanical vibrations.

List of Laboratory Equipment:

- ECP-310 Mass-Spring-Damper System

- LDS Electro-Magnetic Vibration Shaker

- Rotational system instrumented with various vibration measurement sensors to demonstrate the shaft vibration, monitoring, and control

- Hand-held vibro-meter to measure displacement, velocity, and acceleration

- Piezoelectric Accelerometers, non-contact type eddy-current displacement sensors, rotary encoders, etc. for vibration measurement

- Elastomeric and spring-mounted vibration isolation devices